The unemployment statistics are published monthly on the website run by the Bureau of Labor Statistics and there are many analysis reports supporting the published rate data.

The persistently high unemployment rate is broken down by segment in a occupation based table with every segment showing a very flat 2010. Statistics are for November 2010 vs. November 2009. On January 7, 2011, we can see December's numbers.

Will the recovery begin to add 100,000 jobs a month on average any time soon?

We are finishing the year with gas prices above $3 in most regions. This is high for this time of year. We are far from the high $4 to $5 a gallon we lived through during the summer of 2008.

The folks on AgWeb have a 17 minute audio clip focusing on high prices for grains. The clip is produced mainly for the farming industry. The industry benefits from high prices they can sell their grains for in the short run.

The worldwide demand for both food and fuel will have a major impact on the 2011 economy.

Rabu, 29 Desember 2010

A Review of the Outlook for 2010

Around this time of year, many people give their outlook for the coming year. In my blog post Outlook for 2010 I made several predictions. All but one of the forecast items proved true:

We can expect the Federal Reserve to leave rates low until the job market turns the corner.

The overnight rate stayed between 0 and 1/4% for the entire year.

Increases in government spending at the federal level will be partially offset by cuts in local and state government budgets.

State and local governments were definitely in cut mode. The federal government spending was huge as the stimulus money was spent in many areas. Here in Northern Virginia, we see the new Metro link from Tysons Corner to Dulles Airport project dominating the landscape.

Somewhere in the later half of 2010, I expect the job market to reverse course as employers slowly start adding people to their payrolls.

Unemployment remained stubbornly high with no relief the entire year.

Stocks should continue the up and down motion as the Dow Jones seeks higher ground.

Wall Street is in the green for 2010. All key indexes are up for the year and we are currently enjoying a year end rally.

Any increase in consumer confidence will translate into profit since companies have reigned in their fixed costs. Will restaurants start filling their dining rooms mid-week?

Despite lots of restaurants seeking Chapter 11 bankruptcy protection early in the year, the industry is flat to up and creditors are allowing most reorganization plans to gain approval.

Look to travel indicators for signs of increased mid-week business. When airlines and hotels begin to see increased volumes, restaurants will find business travelers in their seats. Don't expect many $100 bottles of wine on business expense accounts this year. Frugal is in vogue.

Hotel occupancy rates have improved and the year end party news from downtown Manhattan had a frugal flavor.

I expect oil to remain below $100 per barrel.

I'm still accurate with this prediction but the markets are unseasonably high as 2010 comes to a close.

Overall, 2010 will be better than 2009 as the long slow recovery takes root.

Overall, 2010 was a big improvement over 2009 for most Americans. The big group experiencing persistent unemployment is a notable exception.

We can expect the Federal Reserve to leave rates low until the job market turns the corner.

The overnight rate stayed between 0 and 1/4% for the entire year.

Increases in government spending at the federal level will be partially offset by cuts in local and state government budgets.

State and local governments were definitely in cut mode. The federal government spending was huge as the stimulus money was spent in many areas. Here in Northern Virginia, we see the new Metro link from Tysons Corner to Dulles Airport project dominating the landscape.

Somewhere in the later half of 2010, I expect the job market to reverse course as employers slowly start adding people to their payrolls.

Unemployment remained stubbornly high with no relief the entire year.

Stocks should continue the up and down motion as the Dow Jones seeks higher ground.

Wall Street is in the green for 2010. All key indexes are up for the year and we are currently enjoying a year end rally.

Any increase in consumer confidence will translate into profit since companies have reigned in their fixed costs. Will restaurants start filling their dining rooms mid-week?

Despite lots of restaurants seeking Chapter 11 bankruptcy protection early in the year, the industry is flat to up and creditors are allowing most reorganization plans to gain approval.

Look to travel indicators for signs of increased mid-week business. When airlines and hotels begin to see increased volumes, restaurants will find business travelers in their seats. Don't expect many $100 bottles of wine on business expense accounts this year. Frugal is in vogue.

Hotel occupancy rates have improved and the year end party news from downtown Manhattan had a frugal flavor.

I expect oil to remain below $100 per barrel.

I'm still accurate with this prediction but the markets are unseasonably high as 2010 comes to a close.

Overall, 2010 will be better than 2009 as the long slow recovery takes root.

Overall, 2010 was a big improvement over 2009 for most Americans. The big group experiencing persistent unemployment is a notable exception.

Minggu, 05 Desember 2010

Morningstar Perspectives Features a Knowledge@Wharton Study

Warming up for my Outlook 2011 post, I discovered the excellent Perspectives column on Morningstar.com. This week, they clipped a study by Knowledge@Wharton on Post-Recession America. The study uses information from the recent census.

A startling statistic is the number of Americans living below the poverty level. One in seven people are living on incomes deemed below the poverty level. This is the highest rate of poverty since they made these statistics available in the 1960s.

Friday's unemployment rate increase to 9.8% is another reminder of the very slow pace of the recovery.

Back to the Knowledge@Wharton article, they cite falling incomes and birth rates. The drops were measured using 2009 vs. 2008.

I would characterize the mood of the article as somber but they had a hopeful ending for the poor. They expect the poverty rate to decline quickly as the employment picture brightens.

A startling statistic is the number of Americans living below the poverty level. One in seven people are living on incomes deemed below the poverty level. This is the highest rate of poverty since they made these statistics available in the 1960s.

Friday's unemployment rate increase to 9.8% is another reminder of the very slow pace of the recovery.

Back to the Knowledge@Wharton article, they cite falling incomes and birth rates. The drops were measured using 2009 vs. 2008.

I would characterize the mood of the article as somber but they had a hopeful ending for the poor. They expect the poverty rate to decline quickly as the employment picture brightens.

Senin, 29 November 2010

Q&A Recipe Costing and Cost Accounting

rey said...

Hi Joe.

I hope I'm posting this in the correct blog.

In order to cover our waste, free bread, staff food, and complimentaries, we are planning to add a plate cost to our new recipes to cover these costs. We understand that this will push our selling prices up.

My question is as follows:

Do we add the plate cost to the recipe or do we simply raise the selling price by the respective plate cost?

Ray

Kurt_Woloch said...

@Rey:

I know I'm not Joe, but I wanted to chime in on this...

I would look at this differently. Let's look at each of the items you named:

Waste... should be attributed to the item that gets wasted. For instance, if you buy 5 potatoes, but regularly throw away one of them, the purchase price of the 5 potatoes has to be divided by the 4 potatoes that actually get used.

Free bread... free with what? Does every customer get this, even if only drinks are consumed? Or does the bread come with meals, or even only with some meals, but not all? In that case I would try to determine how much bread in average gets used for each meal on the menu and add the price of that average bread consumption to the recipe of that dish, respectively.

Staff food... should correctly be attributed to staff costs like wages. I would factor the cost of staff food into the wages, so the more time gets used on an item, the more staff food cost gets factored in.

Complimentaries... here I would ask myself what exactly causes them. There can be various reasons, and I don't know yours, but if the ordering of certain items typically leads to complimentaries being issued, I would factor the cost of complimentaries into those items that causes them.

Kurt has made several excellent points. On the terminology angle, I consider the "waste" example describes standard yield. Using the 4 usable potatoes out of 5 purchased example, we would expect to use 50 pounds of potatoes for each 40 pounds called by a standard recipe. Some people prefer to assume 100% usage and treat normal loss of weight to trim as shrinkage. The deli business uses the term shrinkage to describe all weight losses.

If they receive revenue for 20# of product they used 25# of product, we could say their shrinkage was 20%. They include standard yield, spoilage and other loss of weight in their calculation.

Should you charge for this "waste", "shrinkage", "standard yield", etc.?

I recommend allowing for expected trim loss in your recipe costing and menu item pricing formulas. The allowance for an acceptable level of spoilage may be added if your menu varies and your customers expect to pay a higher price. It is not as easy to pass along the cost of spoilage in this economy. Value conscious guests may look elsewhere if they feel your prices are too high.

Employee meals are related to direct labor costs and the food consumed is a component of your cost of goods sold. There are two ways to manage this activity. You can budget a cost of one meal per employee shift ($3.00 is used by many companies). Alternately, you can calculate the true cost of the food served to employees and deduct this from your overall food cost.

I have no strong opinion regarding the best way to handle employee meals cost. I strongly recommend setting a policy and adhering to the method in a consistent manner. Say you have no credit for employee meals today. You implement a new policy of charging $3 per shift. Any comparisons to previous food cost performance are erroneous. Don't go around patting yourself on the back because you began crediting employee meals.

Regarding free bread, I had a conversation with a friend the other day about a "best restaurants" cover in a local magazine. A prominent local TV celebrity was photographed with his wife dining at a popular restaurant. The table included a completely untouched bread basket, his burger plate and her salad plate. We were discussing why too many restaurants offer free bread at lunch to patrons who may be ordering a sandwich. Do you ask your guests if they would like some bread with their lunch?

I see lots of untouched bread baskets during the lunch service.

Some restaurants try to up-sell the freebies placed on the table before any orders are taken by the wait staff. Chips and salsa may be upgraded to guacamole and chips. Garlic bread may appeal to some of the free bread lovers. Some of your guests may make a meal of the preliminary course. You need to be careful.

A friend of mine milks the preliminary offerings to the max. If the restaurant serves olive oil, he'll ask for extra and sometimes they bring a bottle. One place we enjoy serves bruschetta. He requests extra topping and the servers always return with a generous amount in a small bowl.

You absolutely should charge for the complimentary items somewhere in your menu prices. One of my favorite Upstate New York restaurants offers access to a small salad bar along with a mini loaf of fresh baked bread once you place your order (half chicken is the most popular choice). If they didn't build the cost of the salad bar and bread in their prices, they would be in deep trouble. On my last visit, I paid below $10 for the meal.

Selasa, 23 November 2010

Forecasts For Better Food Cost Results

Most restaurants have an automated ordering system (POS) which can be queried for menu item counts for any given data range. This data is quite helpful for the forecasting team in restaurants using a limited menu or a menu with a central focus (either by cuisine or main ingredient). Unwieldy menus do not allow a quick menu item count forecast (using historic POS data) to effectively buy most key items.

At the core, most forecasts begin with the cover count or number of guests expected to arrive in a given time period. Adding the check average to this cover forecast will provide the people designing a shift schedule with a target. Simply take the covers times the check average times the target labor percentage. This is the budget for the period.

Food cost control is not a percentage game in the planning phase. Although most use food cost percentage to measure results, the number won't help you predict what food to order, store, prep and bring to the line for any given period. Cover counts and check averages will provide a broad target. Making the target work is a tougher task.

For many raw ingredients, the ability to use unsold product in future meal periods has a significant impact on your food cost results. Limited menus put a short list of ingredients in play every single day. They don't need to worry how to use any leftover cheese at Domino's Pizza. Pizza is on the menu tomorrow. In contrast, operators using menus relying on daily specials for a major share of sales will have a much more demanding job to use up leftover stock.

The purchasing forecast depends on par stock targets for many shelf stable items. In a typical kitchen, a much greater share of the food cost dollar is spent on perishable meat, fish and produce. The error penalty for over ordering a shelf stable condiment is minimal when compared to fresh white fleshed fish. You will often see seafood specialists with chalkboards. Late in the dinner shift on a busy night, they want to run out of fish if the next day's forecast is for a slow Sunday or Monday.

My favorite Italian restaurant in New York does not offer fish on days when the fish market is closed (Saturday and Sunday). Some chefs pay air freight to get fresh fish in the door as fresh as possible. You want to avoid over buying any highly perishable raw ingredient. Just ask your self a simple question: "If I order more than I can use today, will I be able to sell the leftovers tomorrow?"

Once you move away from fresh fish and poultry, dairy and produce are highly perishable and are frequently purchased by specialists. If your operation doesn't justify hiring a specialist, tracking produce waste can help you adjust your pars quickly. I favor either a two-tier or three-tier par stock model. Order more before busy days and less on slow days.

I believe using sophisticated software (with menu item counts, standard recipes, standard yields and other recipe model factors) are most useful for companies who have never explored these tools. Often, my clients tell me they wish they had analyzed their menu item costs years ago.

The knowledge gained from yield analysis really improves future forecast accuracy. If you learn to translate purchase units of measure into the number of standard portions, you will have a competitive advantage. Your forecast model can now go well beyond covers, check averages and percentages. Take your top 25 items and buy more precisely. The impact is huge.

At the core, most forecasts begin with the cover count or number of guests expected to arrive in a given time period. Adding the check average to this cover forecast will provide the people designing a shift schedule with a target. Simply take the covers times the check average times the target labor percentage. This is the budget for the period.

Food cost control is not a percentage game in the planning phase. Although most use food cost percentage to measure results, the number won't help you predict what food to order, store, prep and bring to the line for any given period. Cover counts and check averages will provide a broad target. Making the target work is a tougher task.

For many raw ingredients, the ability to use unsold product in future meal periods has a significant impact on your food cost results. Limited menus put a short list of ingredients in play every single day. They don't need to worry how to use any leftover cheese at Domino's Pizza. Pizza is on the menu tomorrow. In contrast, operators using menus relying on daily specials for a major share of sales will have a much more demanding job to use up leftover stock.

The purchasing forecast depends on par stock targets for many shelf stable items. In a typical kitchen, a much greater share of the food cost dollar is spent on perishable meat, fish and produce. The error penalty for over ordering a shelf stable condiment is minimal when compared to fresh white fleshed fish. You will often see seafood specialists with chalkboards. Late in the dinner shift on a busy night, they want to run out of fish if the next day's forecast is for a slow Sunday or Monday.

My favorite Italian restaurant in New York does not offer fish on days when the fish market is closed (Saturday and Sunday). Some chefs pay air freight to get fresh fish in the door as fresh as possible. You want to avoid over buying any highly perishable raw ingredient. Just ask your self a simple question: "If I order more than I can use today, will I be able to sell the leftovers tomorrow?"

Once you move away from fresh fish and poultry, dairy and produce are highly perishable and are frequently purchased by specialists. If your operation doesn't justify hiring a specialist, tracking produce waste can help you adjust your pars quickly. I favor either a two-tier or three-tier par stock model. Order more before busy days and less on slow days.

I believe using sophisticated software (with menu item counts, standard recipes, standard yields and other recipe model factors) are most useful for companies who have never explored these tools. Often, my clients tell me they wish they had analyzed their menu item costs years ago.

The knowledge gained from yield analysis really improves future forecast accuracy. If you learn to translate purchase units of measure into the number of standard portions, you will have a competitive advantage. Your forecast model can now go well beyond covers, check averages and percentages. Take your top 25 items and buy more precisely. The impact is huge.

Selasa, 02 November 2010

Essential Food Cost Control - All You Can Eat Operations

Dear Sir,

I have recently joined as trainee accountant and been assigned to conduct an audit of a catering project. However, I am clueless on how to arrive at a food cost. Below are the three targets I was provided and while I was looking over internet I found your blogs to be helpful. Can you please provide me any formula or a table that can be of help?

Check cost per man day and whether it has been under control as foreseen in the costing.

Check the menu and cost whether it complies according to the contractual stipulations.

Fix budget for cost centers and follow up in the subsequent months whether the expenditures are under control or not.

Thanks in advance sir.

Regards,

R

The key to success for your operation is in a complete understanding of the cycle menu. Certain weeks will run higher food costs. You will find certain days of the week run high and other days much lower. Once you get a feel for your menu and the patron preferences, your cost data will help you track the actual results vs. the plan.

Cost center analysis is best accomplished through head counts by meal period. Track the number of patrons for each meal period and for each dining area.

A cost per man day is a composite number which depends on the total cost of all food consumed. Slicing and dicing the total cost requires tracking patron attendance and food production. You'll get on top of the formula quickly by tracking details of the patron attendance and the traditional food cost formula:

FOOD COST = BEGINNING INVENTORY + PURCHASES - ENDING INVENTORY

Count data should be gathered by day in the cycle, meal period, dining room and any special event details. Really, there is no specific pattern to follow. Your contract will have details which will guide your selection.

Quantity Food Production Skills

Hi Mr Dunbar,

How are you. Sorry to barge in like this but as a new entrant I need your help. I was a kitchen manager in an a-la-carte restaurant with my staff cooking for small tables.

I recently got a new job as production manager for banquets at [a major sports venue]. The issue here is that there is a sudden transition from line cooking to volume/bulk cooking. My Director of Operations asked me today if I can to make a changeover from line cooking to volume cooking. I am supposed to instruct and lead the cooks in what they do.

No more a la carte but 4 buffets serving 125 to 150 people who come to see the [sports events]. What do you think the issue is? I suddenly can’t cook bulk as a demi-chef since I don't have the experience. Are there any books which cater to this situation? How do you transition from a la carte cooking to bulk cooking, when you have the theory but no knowledge of volume cooking? Any help will be really appreciated.

Chef

Buffet food production in a sports arena requires accurate forecasts. The teams may go on the road and leave you with a walk-in cooler loaded with leftovers. On the other hand, you don't want to stock out on game day.

Unlike an a la carte menu, a buffet deals with a set layout. You know what to produce but you don't know exactly what will be most popular. Once you get some data, the puzzle will be easier to solve.

I prefer a matrix for tracking buffet results. The rows are the buffet components and the columns track the activity. The first column is my forecast and I try to relate the PRODUCTION forecast to the service line. For example, if an item is served in a pan I would forecast the number of pans. The next column SERVED is the number of pans consumed by guests. I finish the simple table with a WASTE column.

You may be able to use some of the food in a future event but be careful. Recently, I was sickened by a meal I had at a football game. The service style was buffet and the food was not uniformly hot. Bringing the temperature of full pans down below the danger zone for bacteria, reheating days later and sending the pan back on a serving line is risky business.

Imagine you are serving 100 people. Take the buffet layout and take each menu item separately. Guess how many ounces each patron will consume. Don't use 12 ounces or 8 ounces as you would in an a la carte operation. Try 3 or 4 ounces for popular items. Use a lower figure for less popular items. This is your forecast base.

Kamis, 28 Oktober 2010

Using Mark Ups Instead of Food Cost Percentage

Hi Joe,

I like your site, excellent information.

I am looking for a resource that explains why operators would use ‘mark-ups’ of factors over FC%.

I teach food costing to our chef students and always use FC% to get a selling price, but now I have to explain the other options but can’t seem to find good definitions of why you would use the other options of obtaining selling price.

Could you offer any advice?

Kind regards

Mark Caves

Culinary Arts Tutor

School of Tourism and Hospitality

Faculty of Arts and Social Sciences

Eastern Institute of Technology

Hawkes Bay

New Zealand

Thanks for the question Mark.

During my corporate years, we never used food cost % since our billing method was per man per day. To get more current, it helps to use a destination resort for an illustration. Many resorts located in the mountains offer a complete package including room based on double occupancy, all meals and snacks, and optional activities.

We were big fans of these hotels and inns when we lived in Quebec. You can get a fantastic price for mid-week visits. Any operator who wants to offer a competitive all-inclusive price needs to know their costs to the penny.

Caterers should not use food cost percentage to control their costs if they offer packages. In my July 2008 post Profitable Special Events , there is a chart designed to show the impact of raising $200,000 of additional revenue. I included the % analysis to be complete but the focus was on the cost per guest for each cost component (including profit).

Many caterers and hotels negotiate a final price in a competitive environment. If the sales team does not have a hard deck figure, you may find yourself working very hard for free.

Why do percentages fail in these operations?

One of my early catering clients was barely breaking even. He was an attorney with a major investment in a catering hall. When we met the first time, he was shocked he couldn't break even although his 25% food cost number was well below the 32 or 33% figures mentioned in the book he used to put together his business plan.

I asked him what he used for the divisor.

He was dividing his net food purchases by total sales. Many of the events were cocktail receptions held in the evening hours. Guests were treated to a full bar with several stations and hors d'oeuvres served by wait staff. I asked him what his bar cost % was for the same period of time. Due to his belief in serving top shelf liquor and premium beers and wines, his bar cost percentage was 14% of total sales.

The combined cost of goods sold was almost 40%. I explained what he needed to do to cover his costs and produce a reasonable profit. He had 2 options: raise prices or reduce costs (or a combination).

Food cost percentage analysis is also mediocre for buffet management. Any all-you-can-eat buffet operation would get a better view by tracking layouts and components. There are strategies for controlling high cost proteins and promoting low cost desserts. A simple food cost % tells you very little about this type of meal service.

Senin, 25 Oktober 2010

Purchasing and Food Cost Results

Hi Joe,

Your site is the best thing I've ever found on food cost.

I have a question and was hoping you could help me clarify something:

Is my food cost percentage affected by high purchase amounts? I understand that my Food Cost will be high as the value of my inventory will be high, but in terms of % versus sales does it really affect it?

Let's say theoretically, I do over purchase, but none of what is purchased spoils and I don't waste anything except for my usual amount of waste in production. Essentially my food cost should stay near to where it usually is correct?

Thanks,

Steve

Operations Manager

Yes. Just don't make it a habit. Chronic over ordering will certainly impact your food cost results in a highly unfavorable manner.

Your food cost always equals net purchases. The percentage simply relates the net purchases to your sales volume. In fact, most operators do over purchase food. Their #1 concern is running out of stock. Most ordering models have a safety factor built into the formula.

Problems often show up in an indirect way. I have seen employees served crab cakes and roast filet mignon for lunch. Freezers packed with protein items originally purchased fresh and stored in the refrigerator show a high ending inventory total. "Blowout specials" are used to "burn off" perishable items lowering sales and increasing the food cost percentage.

Like any industry, we suffer from a lack of flexibility anytime our ending inventory is inflated. Simply stated, your chef won't be able to take advantage of future opportunities if he becomes concerned with proper use of the current stock. In fact, this focus can really produce catastrophic results when you start to look at rehashing protein items.

I will offer an extreme example. This example happens to be a true, real-life story. A chef gets a call from a seafood salesman in Alaska. The salesman knows the chef enjoys working with fresh caught Alaskan salmon and halibut. The deal involves an order of 25# of fish with free air shipment.

On the delivery day, the UPS driver was sick and his replacement went to the restaurant at the wrong hour (they are a dinner house). The fish made the complete route tour before landing back in the UPS warehouse.

The chef had a person try to locate the driver on his route most of the afternoon. This employee drove over 30 miles in Friday rush hour traffic. Eventually, he went to the warehouse and waited for the fish. At 6 PM, he got his hands on the box and the chef had the salmon at 7 PM. Of course, he was compensated for his time and gas used.

The wait staff began pushing the salmon special later in the dinner shift since the fish needed to be prepped and the manager needed to add this special to the POS system. The special was not included on the original printed specials page. It was immediately added to the chalkboard. Menu pages were reprinted.

They sold 75% of the fish over the weekend despite the problems. By Monday, the remaining salmon was frozen. Did the chef get a good deal?

To his credit, he did not offer a "blowout special" on the slow Monday. Alaskan salmon changes dramatically in taste and texture once you freeze and thaw the fish. The frozen product was eventually used in a fish soup.

The story illustrates some of the issues you need to consider. A small amount over purchased in your low point of the week will be consumed in a special during the busy times. However, a large buy for the busy days will not be consumed on a slow night. When the salmon was eventually used in the soup, there were plenty of local fish species available for a fraction of the price paid for the air shipment.

As you increase the number of protein options on your menu, the likelihood of waste and spoilage does increase. Your assumptions may not jive with reality once the number of protein options hits 10. If you serve a diverse menu, you expect to live with a manageable level of spoilage and waste. When this level becomes too high, the food cost percentage will suffer.

Rabu, 20 Oktober 2010

Food Cost Formula Illustrated

I have been active using email with HT this week. His company does not track food cost using a percentage target. This is the way we were trained in my role as operations auditor with Sodexo on remote site feeding projects.

HT works on a drilling rig. Although most North American remote sites from my days in the 1980s are now cities and towns with airports, shopping centers and good roads, drilling rigs will always need support services.

We have emailed each other in order to clarify the billing policies on his contract. Unlike our contracts which allowed billing for a full manday as long as a resident attended at least one meal, on HT's jobs they only bill for the meals attended. The clarifications and a revised spreadsheet follow.

The resulting control model carefully tracks the budget per meal applying the correct target cost per meal. This analysis shows the maximum food cost total which will meet our budget target. The actual food cost is determined by the traditional formula [Beginning Inventory + Purchases - Ending Inventory = Food Cost].

Returning to our previous example, I have added the actual cost data and a variance field.

For those of you who live and die by the FC%, you may find the meal method helpful. I like the meal method to test the impact of dayparts on the food cost results. The focus is on dollars (or your local currency) vs. percentage. Your percentage results will improve by adding this tool to your kit.

When you track your costs by meal, you will develop a food cost system which will produce a true variable cost. Fluctuations caused by seasonal issues and busy day/slow day issues will be eliminated. You may need to track your employee meals more carefully. We treated each employee meal the same as a billable meal. The idea is to track your food used based on a budgeted cost per meal.

Most POS systems will have a report which recaps the check average by meal period. These check averages will help you develop a per meal budget. Changes in customer habits (like a shift from soft drinks to complimentary tap water) are easier to track. Customer profiles will help you think through the menu pricing decisions in a strategic manner. The QSR operations have done a great job developing value meals. I have always been a fan of the table d'hote option for dinner houses.

Try tracking your costs by the meal or guest and you will see your food cost in a new light.

HT works on a drilling rig. Although most North American remote sites from my days in the 1980s are now cities and towns with airports, shopping centers and good roads, drilling rigs will always need support services.

We have emailed each other in order to clarify the billing policies on his contract. Unlike our contracts which allowed billing for a full manday as long as a resident attended at least one meal, on HT's jobs they only bill for the meals attended. The clarifications and a revised spreadsheet follow.

Clarifications:

Q. So 1.5 is 15% of 10. We expect breakfast to be 15% of food consumed. This is what I call a target (a goal).

A. OK

Q. The count for each meal just explains how many showed up for the meal. What if someone only came to a single meal but ate like a horse, do we get a complete manday? or only the 1.5 divided by 10 if breakfast?

A. He will be calculated at the times he would eat.

If he attends breakfast only then YES 1.5 divided by 10 for the numbers who have attended the breakfast then the number of those attending lunch and so on then we add up all and this would be the MEN ON BOARD count since there is a price for each of the meals.

Q. On our jobs, if they ate even one meal we billed the entire day. This is one part I do not understand for your project.

A. You see, that's why the lunch is the most expensive cause we would have low numbers and even near to steady numbers on all meals except for the lunch where there will be visitors.

The resulting control model carefully tracks the budget per meal applying the correct target cost per meal. This analysis shows the maximum food cost total which will meet our budget target. The actual food cost is determined by the traditional formula [Beginning Inventory + Purchases - Ending Inventory = Food Cost].

Returning to our previous example, I have added the actual cost data and a variance field.

For those of you who live and die by the FC%, you may find the meal method helpful. I like the meal method to test the impact of dayparts on the food cost results. The focus is on dollars (or your local currency) vs. percentage. Your percentage results will improve by adding this tool to your kit.

When you track your costs by meal, you will develop a food cost system which will produce a true variable cost. Fluctuations caused by seasonal issues and busy day/slow day issues will be eliminated. You may need to track your employee meals more carefully. We treated each employee meal the same as a billable meal. The idea is to track your food used based on a budgeted cost per meal.

Most POS systems will have a report which recaps the check average by meal period. These check averages will help you develop a per meal budget. Changes in customer habits (like a shift from soft drinks to complimentary tap water) are easier to track. Customer profiles will help you think through the menu pricing decisions in a strategic manner. The QSR operations have done a great job developing value meals. I have always been a fan of the table d'hote option for dinner houses.

Try tracking your costs by the meal or guest and you will see your food cost in a new light.

Senin, 18 Oktober 2010

Calculation of Food Cost Per Man Per Day (Man-Day)

Hi Joe,

I am really grateful for your prompt answer and the time you dedicated to answer my query. I apologize for not presenting full information as I had serious doubts I would receive an answer!

Allow me to present these facts:

1-My objective is to calculate the cost per man/ day ( breakfast, lunch, dinner and midnight)

2-The known facts every day are :

a) the number of meals presented to the client which you have inserted in the first matrix

b) the total cost of the food ingredients for all meals together.

3-If the 4 meals presented every day cost = 10 then the Company base its calculation on the following ratio: Breakfast = 1.5, Lunch = 3.5, dinner = 2.5 and midnight = 2.5

Once again, I thank you dearly and look forward receiving your feed back.

Best regards

HT

I worked in the remote site feeding and support services division of Sodexo for 9 years. We tracked all of our costs per man-day. If you carefully track your cost of all ingredients each day and divide this sum by your manday count, you'll arrive at an actual cost per man-day.

The other meal level information is your standard cost data. You need to hit 10 per man-day and you have targets for each meal period. I would recommend you divide the day into two parts - Midnight/Breakfast (target is 4) and Lunch/Dinner (target is 6). You can isolate most operational problems and focus on a solution if you get closer to the actual variance.

You may find the 1.5 breakfast target is too low but the lunch target of 2.5 is too high. Of course, you could look at each meal independently each day.

On our camps, we served large beefsteaks twice a week. Workers (our customers) consumed over 5,000 calories per day. They were working hard in the frigid regions of Northern Canada and Alaska. Steak Nights were a major component of our food cost results. We knew the cost of the steaks served and the average number of steaks consumed since the impact was high.

We served buffet style meals in an all-you-can-eat format. Our guests were served the entree and sides by one of the chefs or cooks. All salads, desserts, rolls, etc. were self-serve. Beverages were self-serve.

Our team knew the cost of the salad bar, the dessert station, the beverage station and average condiment usage. The cost of the items served by our main line varied based on a cycle menu.

If your operation is similar to the one I described, I recommend using a week as your report period. Most cycle menus will begin to track a tight cost range for each week of the cycle. You will find great variations on the dinner meal period based on the day in the cycle and the cost of the protein and produce items.

Calculating Average Food Cost for Multiple Meal Periods

Hi,

Thank you for your article "Food cost basics" which is published in foodservice resources.

I have an inquiry related to food costing and I hope you could help me figure it out:

If I am serving 20 Breakfast, 30 lunch, 50 Dinner and 10 midnight meals for the same customer , how could I calculate the average food cost per person knowing that the cost of the meals are as follows : breakfast =1.50, lunch and dinner = 3.00 and midnight meal is 2.50?

I hope you can help me on that.

Thank you and best regards,

Hesham

Let's take a look at the information you supplied. This information is essential to answering your question. To illustrate my first view, I have created a quick spreadsheet:

We have enough information to calculate the average cost per meal. The spreadsheet shows the process which involves 3 steps:

A. Multiply the cost of a meal by the meal count for each meal period.

B. Add the total meals and total costs.

C. Divide the total costs by the total meals to find your average cost per meal.

Food cost percentage involves relating the average cost per meal to a sales per meal. Since I don't have this data, I have used sales prices which would produce a food cost equal to one third (1/3) of my costs (33.3%). If I had the actual sales prices, I would have constructed a second spreadsheet:

Your food cost percentage depends on your sales and your costs. For each meal period, you need to multiply the price times the count to get your sales for each period. Add the sales and divide your total costs by your total sales.

Kamis, 30 September 2010

Lower Food Costs Provide Edge

In an article written by Jeremiah McWilliams in Tuesday's Atlanta Journal Constitution, Sara Senatore, an analyst with Sanford C. Bernstein, is quoted regarding the impact of rising corn prices. She said "eventually that's going to trickle into protein..." in a discussion about poor crop conditions and rising demand for corn.

The article also mentions the ability of major chains to dampen the impact of rapid price increases through use of future contracts. However, many of these long term contracts will be expiring in the months ahead.

There is some speculation regarding the expected reaction on the part of major chains. Will they be able to continue to win the futures game? Will they pass along the impact of rising prices to their customers through higher menu prices? Will they simply eat the higher prices they will pay for food?

Most likely, we will experience all three reactions. The industry leaders will continue to sign long term contracts with farmers and food producers. Menu prices will likely increase and companies may need to absorb the market price spikes on their second tier food items.

Companies with tight cost controls will enjoy a major advantage. They will benefit from clear reports which will help them manage the inflationary environment. By measuring the impact on their specific operations, higher protein and grain prices can be managed effectively.

You may find less customer resistance to higher menu prices as the chains react to the higher corn prices. If you successfully raise prices, retain customers and control your food cost, you will gain a huge edge over your competition.

The article also mentions the ability of major chains to dampen the impact of rapid price increases through use of future contracts. However, many of these long term contracts will be expiring in the months ahead.

There is some speculation regarding the expected reaction on the part of major chains. Will they be able to continue to win the futures game? Will they pass along the impact of rising prices to their customers through higher menu prices? Will they simply eat the higher prices they will pay for food?

Most likely, we will experience all three reactions. The industry leaders will continue to sign long term contracts with farmers and food producers. Menu prices will likely increase and companies may need to absorb the market price spikes on their second tier food items.

Companies with tight cost controls will enjoy a major advantage. They will benefit from clear reports which will help them manage the inflationary environment. By measuring the impact on their specific operations, higher protein and grain prices can be managed effectively.

You may find less customer resistance to higher menu prices as the chains react to the higher corn prices. If you successfully raise prices, retain customers and control your food cost, you will gain a huge edge over your competition.

Sabtu, 25 September 2010

Corn's Impact on Food Cost

A brief history (7 year) of corn prices shows we have entered a new long tern pattern. In 2004, prices for corn and soybeans spiked (from 250 to 325) and the rapid increase had an impact on meat and poultry prices. The markets returned to their normal pattern and held through 2005. Markets saw constant increases in 2006 ending the year over 400.

There was a breather in 2007 and the market prices fell back to a level just above 300 in the summer before spiking to a year end close in the 500 range. We all remember the $5 gas prices in the election year of 2008. Corn futures skyrocketed to over 750 as ethanol production increased dramatically.

As the economy tanked, the corn market fell in late 2008 and briefly touched 300 before a year end close near 400.

In the most recent 2 year period, corn has traded in a range between 300 and 450. Gas prices have stayed well below $4 and this summer remained below $3 in many states.

If we take an overview, the increased use of ethanol has shifted the corn price curve by 50% from pre-2006 levels to the recent levels. We can expect any economic recovery to put upward pressure on corn prices.

Source: http://futures.tradingcharts.com/

Why is the cost of corn important?

If you are forecasting the year ahead for purposes of pricing your menu and budget preparation, you need to consider the corn price impact. Any nationwide economic growth will increase gas consumption which will increase corn consumption. Even in the recession period, corn is 50% above 2004 levels. An economic pickup will send corn prices above 400.

As national comparable cover counts increase, it is very likely your cost of goods sold will increase at the same rate or faster. Sales increases due to menu price increases would not impact the corn markets. Actual restaurant traffic across the country is the signal. There are signs pointing to solid economic growth in 2011 and beyond. This will help put more money in restaurants but you will see pressure as gas prices increase and your food costs rise.

There was a breather in 2007 and the market prices fell back to a level just above 300 in the summer before spiking to a year end close in the 500 range. We all remember the $5 gas prices in the election year of 2008. Corn futures skyrocketed to over 750 as ethanol production increased dramatically.

As the economy tanked, the corn market fell in late 2008 and briefly touched 300 before a year end close near 400.

In the most recent 2 year period, corn has traded in a range between 300 and 450. Gas prices have stayed well below $4 and this summer remained below $3 in many states.

If we take an overview, the increased use of ethanol has shifted the corn price curve by 50% from pre-2006 levels to the recent levels. We can expect any economic recovery to put upward pressure on corn prices.

Source: http://futures.tradingcharts.com/

Why is the cost of corn important?

If you are forecasting the year ahead for purposes of pricing your menu and budget preparation, you need to consider the corn price impact. Any nationwide economic growth will increase gas consumption which will increase corn consumption. Even in the recession period, corn is 50% above 2004 levels. An economic pickup will send corn prices above 400.

As national comparable cover counts increase, it is very likely your cost of goods sold will increase at the same rate or faster. Sales increases due to menu price increases would not impact the corn markets. Actual restaurant traffic across the country is the signal. There are signs pointing to solid economic growth in 2011 and beyond. This will help put more money in restaurants but you will see pressure as gas prices increase and your food costs rise.

Minggu, 19 September 2010

Production Food Cost

Most restaurants purchase raw ingredients and produce and sell finished menu items. Our management accounting should be structured in a manner similar to a manufacturing operation. The wait staff should be considered the sales force. They meet the customers and help them order a delicious meal.

We find a beehive of activity on or near the production line in most restaurants. The wait staff wants to rapidly fill orders and the production staff handles orders as efficiently as possible given the equipment constraints and staff levels.

Unlike most manufacturers, a majority of food service managers do not track work in progress and finished goods inventory. Our finished goods are immediately delivered to the dining room.

The terms batch recipe, sub-recipe or prep recipe are used to describe the items produced ahead of the meal period. These items are available to the line cooks and are used to produce more complex menu items. Common prep items are sauces, dressings, stocks, casseroles and other items which take longer than the typical meal cycle to produce. Butchering, produce cleaning and other prep activities convert raw ingredients into portioned items and salad mixes.

Food service operators need clear policies to handle these inventory valuation issues. Inventory valuation is important since the cost of goods sold depends on consistent treatment to determine beginning and ending inventory values.

There are many different accounting policies employed by major food service companies. One of the largest hotel management companies in the world does not use food inventory in their balance sheet and income statements. Food cost reflects all food received from their suppliers each period. Other companies do not value any work in progress inventory. These operators use a prep cooler and management's goal is to minimize the amount of food in this zone.

Due to the increase in report complexity, we often miss the opportunity to evaluate the true cost of batch recipe production. The key reason for tracking batch recipe production, including the cost of direct labor, is the ability to compare the total cost with the available packaged goods.

Salad mixes using romaine lettuce are very popular. For many companies, the value added by cleaning and trimming the vegetables and heads of lettuce does not justify the cost increase. The packaged salad mixes offer a high quality alternative with very low labor costs.

Operators are trying to manage relatively high production costs. Salad production involves many hidden costs: transportation of unusable trim, water used to clean vegetables (often left running during the prep), garbage removal to discard the unusual trim, and higher volatility in market costs. The direct labor is not completely hidden but may be cloudy when the workers handling prep also work in other stations.

So what? Why should anyone care about these issues?

The cost of meat and seafood requiring butchering and vegetables requiring prep may be over 50% of your cost of goods sold. You may have significant hidden profit buried in your operation. The amount of hidden profit may justify a quarterly study comparing prep vs. direct purchase on several key items. If you have a policy of producing everything from scratch, you need reports which allow you to monitor production.

We find a beehive of activity on or near the production line in most restaurants. The wait staff wants to rapidly fill orders and the production staff handles orders as efficiently as possible given the equipment constraints and staff levels.

Unlike most manufacturers, a majority of food service managers do not track work in progress and finished goods inventory. Our finished goods are immediately delivered to the dining room.

The terms batch recipe, sub-recipe or prep recipe are used to describe the items produced ahead of the meal period. These items are available to the line cooks and are used to produce more complex menu items. Common prep items are sauces, dressings, stocks, casseroles and other items which take longer than the typical meal cycle to produce. Butchering, produce cleaning and other prep activities convert raw ingredients into portioned items and salad mixes.

Food service operators need clear policies to handle these inventory valuation issues. Inventory valuation is important since the cost of goods sold depends on consistent treatment to determine beginning and ending inventory values.

There are many different accounting policies employed by major food service companies. One of the largest hotel management companies in the world does not use food inventory in their balance sheet and income statements. Food cost reflects all food received from their suppliers each period. Other companies do not value any work in progress inventory. These operators use a prep cooler and management's goal is to minimize the amount of food in this zone.

Due to the increase in report complexity, we often miss the opportunity to evaluate the true cost of batch recipe production. The key reason for tracking batch recipe production, including the cost of direct labor, is the ability to compare the total cost with the available packaged goods.

Salad mixes using romaine lettuce are very popular. For many companies, the value added by cleaning and trimming the vegetables and heads of lettuce does not justify the cost increase. The packaged salad mixes offer a high quality alternative with very low labor costs.

Operators are trying to manage relatively high production costs. Salad production involves many hidden costs: transportation of unusable trim, water used to clean vegetables (often left running during the prep), garbage removal to discard the unusual trim, and higher volatility in market costs. The direct labor is not completely hidden but may be cloudy when the workers handling prep also work in other stations.

So what? Why should anyone care about these issues?

The cost of meat and seafood requiring butchering and vegetables requiring prep may be over 50% of your cost of goods sold. You may have significant hidden profit buried in your operation. The amount of hidden profit may justify a quarterly study comparing prep vs. direct purchase on several key items. If you have a policy of producing everything from scratch, you need reports which allow you to monitor production.

Jumat, 27 Agustus 2010

Menu Engineering Using Excel

During the month, three fellow restaurant consultants have contacted me about menu engineering and recipe costing with specific questions regarding Excel. Excel charts do not automatically create the popular four quadrant chart with Stars, Plowhorses, Puzzles and Dogs (or any of the other 4 quadrant variations). I have accomplished this task using a few third party utilities. In my analysis, recipe costing is accomplished using software specifically designed for this purpose.

I consider the POS system Product Mix report the source of the key data. Since menu engineering is concerned with selling price fluctuations, the PMIX report has all essential data (number sold and selling price) except the cost to produce each item. Most POS systems have Excel file export capability. If you are adept at the table look-up formula, you can place the exported data exactly where you need it in your model.

Generally, I use good old data entry to update the recipe costs using the numbers from the software. Once I have the number sold, selling price and recipe cost, the sophisticated menu engineering and analysis reports flow from Excel. The four quadrant chart is not the only report produced. You can use sorts and filters to generate a tremendous amount of valuable information.

Anyone who wants an all-in-one solution for inventory, recipe costing, purchasing, menu engineering and requisitions really needs to invest in a proper solution. Excel tables are famous for errors in formulas and there is no audit trail for your purchases (which feed all cost calculations).

Many people have asked me for a recommendation. I do not own a restaurant and I do not have a laboratory in my office with 20 different recipe costing programs loaded and ready to test. In fact, many of the popular software solutions come out with substantial improvements each year. It would be a full-time effort for anyone to honestly provide this type of service.

Many of the popular solutions target a segment and do a terrific job. FoodTrak moved from a restaurant model to a hotel/resort model around 2000. They added transfers and requisitions to the essential restaurant reports already in the program. The reasons I tend to work mostly with FoodTrak: longevity and optional cost methods. They have been around since 1980 and I started my company in 1990. If you need FIFO cost numbers, you won't find a better solution for the investment. There are other programs in the six figures range which have true FIFO but I am assuming very few of my readers would invest $100,000 plus for a solution.

There are many programs capable of decent reporting using the last cost method. I encourage anyone on a tight budget to start with one of these solutions for recipe costing needs.

I consider the POS system Product Mix report the source of the key data. Since menu engineering is concerned with selling price fluctuations, the PMIX report has all essential data (number sold and selling price) except the cost to produce each item. Most POS systems have Excel file export capability. If you are adept at the table look-up formula, you can place the exported data exactly where you need it in your model.

Generally, I use good old data entry to update the recipe costs using the numbers from the software. Once I have the number sold, selling price and recipe cost, the sophisticated menu engineering and analysis reports flow from Excel. The four quadrant chart is not the only report produced. You can use sorts and filters to generate a tremendous amount of valuable information.

Anyone who wants an all-in-one solution for inventory, recipe costing, purchasing, menu engineering and requisitions really needs to invest in a proper solution. Excel tables are famous for errors in formulas and there is no audit trail for your purchases (which feed all cost calculations).

Many people have asked me for a recommendation. I do not own a restaurant and I do not have a laboratory in my office with 20 different recipe costing programs loaded and ready to test. In fact, many of the popular software solutions come out with substantial improvements each year. It would be a full-time effort for anyone to honestly provide this type of service.

Many of the popular solutions target a segment and do a terrific job. FoodTrak moved from a restaurant model to a hotel/resort model around 2000. They added transfers and requisitions to the essential restaurant reports already in the program. The reasons I tend to work mostly with FoodTrak: longevity and optional cost methods. They have been around since 1980 and I started my company in 1990. If you need FIFO cost numbers, you won't find a better solution for the investment. There are other programs in the six figures range which have true FIFO but I am assuming very few of my readers would invest $100,000 plus for a solution.

There are many programs capable of decent reporting using the last cost method. I encourage anyone on a tight budget to start with one of these solutions for recipe costing needs.

Minggu, 22 Agustus 2010

Putting Excel to Use in Food Cost Control

I mentioned my love of Excel in last week's post about software. Excel is ideal for 3 aspects of the food cost control environment: organization, complex calculations, and custom reports.

ORGANIZATION:

Most of the food cost control software assumes you have your entire database conceptualized and you simply need to tap enough keys to create the ideal starting point.

Newbies will find plenty of challenges ahead.

Inventory locations, vendors, item categories and inventory sequence are database requirements for phase one. You initially build the item database to aid you in purchase order and invoice entry (the areas requiring 80% of the time once you go live). At the same time, inventory count sheets need to flow from the item database (along with any batch recipe production items).

Excel is a great tool for getting organized. Build columns for the item description, primary vendor, vendor codes, bar codes, category (produce, meat, fish, etc.), storage method (frozen, refrigerated, dry), primary inventory location (where you look to decide when and how much to order), unit of measure data with conversion factors to allow purchases, storage and recipe usage, par levels, alternate item codes (the vendor code for the item you would purchase if there was a stock out).

COMPLEX CALCULATIONS:

Food cost control involves using scalable recipes to forecast production requirements, purchase requirements, and line setup requirements. In addition, plate recipes help you forecast profits, calculate usage variances, and price menu items. The top software will provide plenty of excellent information. Excel can provide you with customer profiles, sensitivity analysis (what-if?), and many other advanced concepts.

CUSTOM REPORTS:

I use a data mining tool to create custom reports for my clients. Typically, the client will send me their favorite report and ask a question: "Can we get all this exactly the way it is AND add a column on the end which....?"

The data mining software creates the calculation field missing in the source report. Mining software always offers several output options including text, CSV, PDF and Excel formats. I often choose Excel since the analyst can take the analysis further if necessary. Excel offers all of the formats mentioned for the final presentation.

ORGANIZATION:

Most of the food cost control software assumes you have your entire database conceptualized and you simply need to tap enough keys to create the ideal starting point.

Newbies will find plenty of challenges ahead.

Inventory locations, vendors, item categories and inventory sequence are database requirements for phase one. You initially build the item database to aid you in purchase order and invoice entry (the areas requiring 80% of the time once you go live). At the same time, inventory count sheets need to flow from the item database (along with any batch recipe production items).

Excel is a great tool for getting organized. Build columns for the item description, primary vendor, vendor codes, bar codes, category (produce, meat, fish, etc.), storage method (frozen, refrigerated, dry), primary inventory location (where you look to decide when and how much to order), unit of measure data with conversion factors to allow purchases, storage and recipe usage, par levels, alternate item codes (the vendor code for the item you would purchase if there was a stock out).

COMPLEX CALCULATIONS:

Food cost control involves using scalable recipes to forecast production requirements, purchase requirements, and line setup requirements. In addition, plate recipes help you forecast profits, calculate usage variances, and price menu items. The top software will provide plenty of excellent information. Excel can provide you with customer profiles, sensitivity analysis (what-if?), and many other advanced concepts.

CUSTOM REPORTS:

I use a data mining tool to create custom reports for my clients. Typically, the client will send me their favorite report and ask a question: "Can we get all this exactly the way it is AND add a column on the end which....?"

The data mining software creates the calculation field missing in the source report. Mining software always offers several output options including text, CSV, PDF and Excel formats. I often choose Excel since the analyst can take the analysis further if necessary. Excel offers all of the formats mentioned for the final presentation.

Selasa, 17 Agustus 2010

Food Cost Control and Excel

Question:

Joe,

I'm looking into buying a menu costing program/software are there any you recommend?

Answer:

I can recommend 2 or 3 solutions. It depends on your long term objectives. Please email me at joe@joedunbar.com so we can pick your ideal solution.

Response from Erik:

From what i have come across, Excel should be the go-to costing program and you should use your own data.

Good point Erik!

I can't think of food cost control without Excel in the picture. The only issue I have is the term "Excel user" has a tremendous variation.

There are people who could model the Big Bang using Excel and other people who haven't discovered the SUM formula (use + sign).

Importing history into Excel is a pain if the files change (for example, a new menu item) for anyone who hasn't mastered Excel's terrific data functions.

Once the power users get everything done conceptually, many migrate the model over to Access so database updates go smoother.

Somewhere along this curve, the benefit of purchasing a software tool specifically designed to handle recipe costing, menu analysis and cost control turns positive.

Many of my clients had terrific Excel based recipe costing models which helped us in building a solution. They often find additional savings of 10% (i.e. if their current Excel control food cost was 30% they would find the new food cost would drop to 27%).

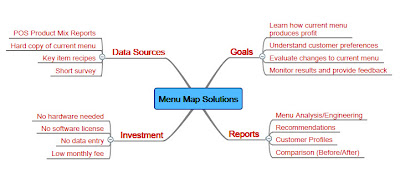

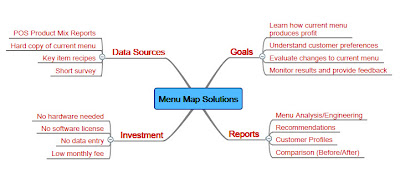

Overall, I believe Excel is the logical starting point for anyone who is serious about getting on top of their food cost. My advanced menu analysis tool - The Menu Map - is 100% Excel based. Since the model focuses on only 3 data points (selling price, food cost and number sold) at the core, Excel is ideal.

Once you want to filter purchase data, Excel loses the power a serious food cost controller needs for investigating problems.

For example, FoodTrak lets you filter invoices by date range, vendor, report group, invoice number, and specific items. There are exception reports to bring many issues to your attention and the terrific data entry alerts show major price variations in real time.

Resorts may need transfer cost reports. This report is a major pain in Excel. Cost updates from purchase data provide freshly costed transfer reports by profit center. Of course, many operations do not have this need. The answer really depends on the operation.

[This post is from comments on the Basic Recipe Costing post.]

Joe,

I'm looking into buying a menu costing program/software are there any you recommend?

Answer:

I can recommend 2 or 3 solutions. It depends on your long term objectives. Please email me at joe@joedunbar.com so we can pick your ideal solution.

Response from Erik:

From what i have come across, Excel should be the go-to costing program and you should use your own data.

Good point Erik!

I can't think of food cost control without Excel in the picture. The only issue I have is the term "Excel user" has a tremendous variation.

There are people who could model the Big Bang using Excel and other people who haven't discovered the SUM formula (use + sign).

Importing history into Excel is a pain if the files change (for example, a new menu item) for anyone who hasn't mastered Excel's terrific data functions.

Once the power users get everything done conceptually, many migrate the model over to Access so database updates go smoother.

Somewhere along this curve, the benefit of purchasing a software tool specifically designed to handle recipe costing, menu analysis and cost control turns positive.

Many of my clients had terrific Excel based recipe costing models which helped us in building a solution. They often find additional savings of 10% (i.e. if their current Excel control food cost was 30% they would find the new food cost would drop to 27%).

Overall, I believe Excel is the logical starting point for anyone who is serious about getting on top of their food cost. My advanced menu analysis tool - The Menu Map - is 100% Excel based. Since the model focuses on only 3 data points (selling price, food cost and number sold) at the core, Excel is ideal.

Once you want to filter purchase data, Excel loses the power a serious food cost controller needs for investigating problems.

For example, FoodTrak lets you filter invoices by date range, vendor, report group, invoice number, and specific items. There are exception reports to bring many issues to your attention and the terrific data entry alerts show major price variations in real time.

Resorts may need transfer cost reports. This report is a major pain in Excel. Cost updates from purchase data provide freshly costed transfer reports by profit center. Of course, many operations do not have this need. The answer really depends on the operation.

[This post is from comments on the Basic Recipe Costing post.]

Selasa, 27 Juli 2010

Question on Food Cost Basics

Joe,

My name is Steve and I am starting a new job as a Sous Chef but haven't learned anything about food costs or labor costs and I am afraid to not be able to be a team player on this important situation, that I am final realizing that its part of my job. Can you please teach me how to do all of this or point me in the right direction. I have read your basics on food cost but still I am having trouble understanding it all. Thank you for your time.

Sincerely

Steve

The goal of food purchasing is to place the food in inventory as close to actual production as possible. People who are pros know delivery dates and times, par stock levels, minimum drops, shelf life, and most important, the forecast for the order period.

The food cost formula is really a report card on how well you forecasted for the orders. Most food service companies have several backup suppliers they can use if they experience sales far beyond the forecast. Typically, these last minute purchases are made at cash and carry stores with much higher prices.

The heart of the food cost formula is purchases. You simply divide net purchases by sales. If you forecast your sales carefully, you will make better purchase decisions.

As a learning tool, you may want to take a look at 4 or 5 weeks of invoices to see past purchases. You can discuss spoilage and waste with the chef. Ordering is most important before busy periods. You need to have adequate supply without creating excessive waste. If you keep score, you will rapidly improve.

Jumat, 23 Juli 2010

Question on Batch Recipe Costing

Hello Joe

My name is Tay. I just purchased a bakery in Minnesota and I would like to know if you can teach me how to estimate the cost of a croissant. Without knowing the formula, I'm afraid not to place the right price. Please give a example. Is there any software on the market?

Thank you very much!

Tay

Thanks for the question Tay.

Gather all the ingredients you need to make a batch of croissants. Write down the amounts of each ingredient required for the batch. This is your recipe.

Using purchase data (use invoices or go to a store if necessary), calculate the cost of each ingredient. You need the cost of the amount used in the recipe not the cost of the entire purchase unit (for example, pound vs. case). Add all the costs to find the batch cost. Once you complete this analysis, you are done with the cost of the batch.

[NOTE: The step above is the trickiest and the most important. For each ingredient, you are asking yourself how many batches you could produce from the common purchase unit of measure (for example, a bag of flour). In the long run, this data is used the most. Prices will change over time but the ingredient quantities will remain the same. Don't rush this exercise. Most recipe software programs call the answer to this question the "Conversion Factor" and it is very important.]

Carefully portion the croissants. Count the croissants. You now have the recipe yield. The formula follows:

Portion Cost = Batch Cost divided by Batch Yield. For example, if you had a batch cost of $45 and you were able to produce 100 croissants, your cost per croissant is $0.45. If you charge $1.50 per croissant, your cost % is 30%.

Kamis, 22 Juli 2010

Mid-Year Look Back - Outlook 2010

My most popular blog post this year is by far the Outlook 2010 which was published in early January 2010. I thought it would be interesting to see how well my predictions have fared during the first half of 2010.

The Federal Reserve Board has cooperated with business borrowers leaving the over night federal funds rate at record low rates (zero to 1/4%).

Despite the BP debacle, the crude oil markets have remained in check and well below the $100 per barrel threshold.

Source: ino.com

Both the Dow Jones Industrial average and the broader S&P 500 index have seesawed back and forth in the search for direction. Corporate profits are definitely higher than 2009.

Source: finance.yahoo.com

There was a short clip on CNBC today regarding higher occupancy rates at the Starwood Hotels group. Many of my clients who have a significant business expense account clientele report a gradually improving climate. Guests are reviewing check totals quite carefully.

We can expect the Federal Reserve to leave rates low until the job market turns the corner.

The Federal Reserve Board has cooperated with business borrowers leaving the over night federal funds rate at record low rates (zero to 1/4%).

I expect oil to remain below $100 per barrel.

Despite the BP debacle, the crude oil markets have remained in check and well below the $100 per barrel threshold.

Source: ino.com

Stocks should continue the up and down motion as the Dow Jones seeks higher ground. Any increase in consumer confidence will translate into profit since companies have reigned in their fixed costs.

Both the Dow Jones Industrial average and the broader S&P 500 index have seesawed back and forth in the search for direction. Corporate profits are definitely higher than 2009.

Source: finance.yahoo.com

Look to travel indicators for signs of increased mid-week business. When airlines and hotels begin to see increased volumes, restaurants will find business travelers in their seats. Don't expect many $100 bottles of wine on business expense accounts this year. Frugal is in vogue.

There was a short clip on CNBC today regarding higher occupancy rates at the Starwood Hotels group. Many of my clients who have a significant business expense account clientele report a gradually improving climate. Guests are reviewing check totals quite carefully.

Minggu, 27 Juni 2010

Optimal Order Size Question

When creating a build to for food orders, what is the exact formula

used? I know it's units used divided by how many days and something to

do with how many deliveries a week.

James

Thanks for the question, James.

Use of the formula described depends on the shelf life of the product. For example, fresh picked raspberries have a rapid spoilage rate when compared to frozen raspberries. The average daily usage/number of deliveries per week model works well for high volume items with a shelf life of 7 days or more.

A twist on this method you may find interesting is to multiply your expected sales (in dollars) by the average consumption per dollar of sales. If you used 1 case for every $1,000 in sales and your sales forecast is for $20,000, you would require 20 cases. Simply check to see what the in stock level is and order the net amount. In our example, we would order 18 cases if we had 2 cases on hand.

Should we order extra in case our sales forecast is off? I think the answer depends on your number of deliveries per week, the day of the order, and your ability to adjust to actual sales volume.

If you are placing a Thursday order for a Friday delivery to handle a busy weekend and you can't get the next delivery until Monday, you would want to provide for a small cushion. On the other hand, a Monday order to replenish your inventory should not be inflated with a safety factor. Your suppliers are most likely in your area all week for any adjustments.

To utilize this method, ask your distributor for a quarterly tracking report. Next you should run a sales recap for the same quarter on your POS system. Divide the number of cases on the tracking report by the total food sales for the quarter. The result is the average usage in terms of sales.

Kamis, 10 Juni 2010

Should You Cherry Pick Spot Prices?

The quotes come in via fax and the internet. You load them into your recipe costing/inventory software. Next, you feed a shopping list to the program and you print the suggested orders. After some minor changes, you send the orders out to as many as 10 vendors. Is this a smart way to buy?

Yesterday, my client and I were on a conference call with a sales rep from Gordon Food Service in Michigan. Our objective is to eliminate waste in the restaurants. I have always recommended weekly inventories but the salesman's advice was twice a week. He wanted us to feed the online ordering system with the inventory counts on Monday and Thursday. Rather than going through the storage areas with a shopping list and jotting down order quantities for under-stocked items, he encouraged my client to take a full inventory.

If you have never been good at inventory control, the journey to tight control absolutely requires a tremendous change in the normal routine.

You may be unwilling to take twice a week inventories for the entire restaurant. Consider phasing in inventories by category starting with protein. In addition, carefully monitor all waste due to spoilage. If you have a sophisticated database loaded with over 100 count values per year, your entire purchasing history and details of your waste, par values will stare you in the face (with seasonal variations).

More importantly, we want to eliminate waste. Ordering too much of a perishable item with a high cost per pound and a major change in taste and texture profile when frozen has to be avoided. As you begin to order the appropriate quantities, your supplier can work with you on the proper pack/size for each item in the non-perishable goods section. They can help you find labor saving alternatives.

I believe it is highly advisable to stay aware of market trends. Whether I would go the cherry picking route in today's marketplace is the question. It's typically a mistake.